Ultra-high Molecular Weight Polyethylene Market Key Points

-

North America accounted for the largest revenue share of 41% in 2024.

-

Asia Pacific is projected to grow at the fastest rate in the upcoming period.

-

By form, the sheets and films segment led the market with the highest share in 2024.

-

The fiber segment is expected to grow at a significant rate in the coming years.

-

By end-user, the medical segment held the largest market share in 2024.

-

The automotive segment is anticipated to grow at the fastest CAGR during the forecast period.

Ultra-High Molecular Weight Polyethylene (UHMWPE): Overview

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a subset of the thermoplastic polyethylene family, characterized by its extremely long polymer chains with molecular weights typically between 3 to 6 million g/mol. These long chains enhance the material’s strength and impact resistance by transferring load more effectively to the polymer backbone. UHMWPE is known for its outstanding abrasion resistance, low coefficient of friction, high impact strength, and chemical inertness, making it suitable for a wide range of demanding applications.

Unlike standard polyethylene, UHMWPE cannot be processed by conventional plastic-forming techniques like injection molding or extrusion due to its very high viscosity. Instead, it is usually compression-molded or ram-extruded into shapes, sheets, or rods.

Key Properties and Applications

Properties:

-

High impact resistance (better than many metals)

-

Excellent wear and abrasion resistance

-

Extremely low friction surface (self-lubricating)

-

High chemical resistance

-

Low water absorption

-

Biocompatibility (safe for use in medical implants)

Applications:

-

Medical: Used in joint replacements (hip and knee implants), orthopedic components, and surgical instruments due to its biocompatibility and durability.

-

Industrial: Liners for hoppers and chutes, gears, bearings, and wear strips in material handling systems.

-

Defense and Sports: Lightweight armor plating, bullet-resistant vests, and high-performance sports equipment like synthetic ice rinks and ski bottoms.

-

Marine: Dock fenders, underwater bearings, and guide rails due to excellent water and corrosion resistance.

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/3050

Ultra High Molecular Weight Polyethylene (UHMWPE) Market Growth Factors

The Ultra High Molecular Weight Polyethylene (UHMWPE) market is experiencing robust growth due to its unique properties and expanding applications across diverse industries. UHMWPE is known for its exceptional impact strength, abrasion resistance, chemical resistance, and low friction coefficient, making it highly desirable in demanding applications. One major growth factor is the rising demand from the healthcare sector, particularly in orthopedic implants such as knee and hip replacements. Its superior biocompatibility, wear resistance, and ability to endure high loads have positioned it as a preferred material for medical-grade components, especially in an aging global population requiring advanced surgical interventions.

Another key driver is the increasing use of UHMWPE in defense, aerospace, and industrial sectors. The material is extensively utilized in the production of lightweight ballistic protection gear, body armor, and helmets, thanks to its high tensile strength-to-weight ratio. In the industrial space, it is widely adopted for manufacturing conveyor belts, liners, gears, and wear plates due to its long service life and resistance to harsh operating conditions. Additionally, the growing need for energy-efficient and durable materials in automotive and electronics industries supports UHMWPE adoption. Ongoing research and development aimed at improving production processes and expanding the application range further reinforce the market’s growth trajectory.

Ultra-high Molecular Weight Polyethylene Market Scope

| Report Coverage | Details |

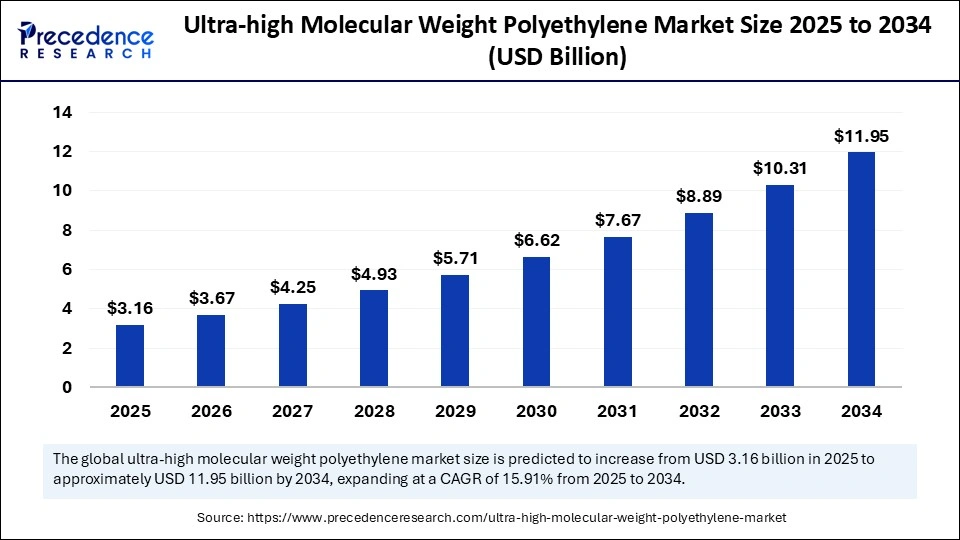

| Market Size by 2034 | USD 11.95 Billion |

| Market Size in 2025 | USD 3.16 Billion |

| Market Size in 2024 | USD 2.73 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 15.91% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Form, End User, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Market Drivers

The Ultra High Molecular Weight Polyethylene (UHMWPE) market is experiencing strong growth driven by its superior performance characteristics, which make it indispensable across multiple industries. UHMWPE is known for its exceptional abrasion resistance, high impact strength, low coefficient of friction, and outstanding chemical resistance. These properties make it ideal for demanding applications in industries such as healthcare, defense, aerospace, and automotive. In the medical sector, UHMWPE is widely used in orthopedic implants, especially for hip and knee replacements, due to its biocompatibility and wear resistance. The rising geriatric population and increasing number of joint replacement surgeries globally are major contributors to market growth.

Additionally, the defense and security sectors are fueling demand for UHMWPE due to its lightweight and high-strength properties, which make it ideal for personal armor, vehicle protection systems, and ballistic-resistant panels. Governments worldwide are increasingly investing in soldier modernization programs and defense equipment, further propelling the market. Furthermore, the growing adoption of UHMWPE in industrial applications such as conveyor systems, food processing equipment, and water filtration membranes also contributes to its expanding market presence.

Market Opportunities

Significant opportunities lie in the increasing demand for sustainable and high-performance materials in emerging economies. Countries in Asia-Pacific, Latin America, and the Middle East are undergoing rapid industrialization and urbanization, which is boosting infrastructure development and the adoption of advanced materials like UHMWPE. Moreover, the growing emphasis on reducing carbon emissions and improving fuel efficiency is driving the automotive and aerospace sectors to seek lighter materials, where UHMWPE fits as a promising solution. This shift is especially relevant in electric vehicles (EVs), where weight reduction is crucial for improving battery efficiency and vehicle range.

In addition, innovations in polymer processing and advances in manufacturing technologies are opening up new avenues for the development of UHMWPE-based composites and blends, expanding its use in next-generation products. The increasing integration of UHMWPE in the production of high-strength ropes, cables, and nets for offshore oil and gas, marine, and fishing industries also presents lucrative growth opportunities. Furthermore, research into biomedical applications—such as drug delivery systems and novel surgical devices—can unlock new potential in the healthcare sector for UHMWPE beyond traditional implants.

Market Challenges

Despite its robust growth prospects, the UHMWPE market faces several key challenges. One major hurdle is the high cost of production compared to conventional polyethylene. The complexity of polymerization and the need for specialized processing equipment add to the overall expense, which can be a deterrent for price-sensitive applications and small-scale manufacturers. This limits its adoption in certain segments where cost efficiency is a primary concern. Additionally, recycling and environmental concerns associated with UHMWPE remain an issue. Unlike some thermoplastics, UHMWPE is difficult to recycle due to its high molecular weight and stability, posing sustainability challenges in a market increasingly focused on circular economy models.

Another challenge is the limited number of global manufacturers capable of producing high-quality UHMWPE at scale. The market is dominated by a few key players, which can lead to supply chain bottlenecks and limited availability for new entrants or niche sectors. Moreover, stringent regulatory standards in sectors like medical devices and defense can create entry barriers and delay product approvals, particularly for new or modified formulations. These regulatory and economic challenges underscore the need for strategic partnerships, technological innovation, and cost-effective production techniques to fully harness the potential of UHMWPE.

Regional Outlook

North America holds a significant share of the global UHMWPE market, driven by strong demand from the healthcare, defense, and industrial sectors. The United States, in particular, is a major consumer due to its advanced medical infrastructure and high defense spending. Additionally, the region’s well-established polymer manufacturing capabilities and presence of leading UHMWPE producers further bolster market development.

Europe follows closely, with countries such as Germany, the UK, and France investing heavily in automotive innovation, industrial automation, and sustainable materials. The region’s focus on high-performance, lightweight, and recyclable materials is fostering UHMWPE’s adoption in various engineering and environmental applications.

Asia-Pacific is expected to witness the fastest growth over the forecast period. Rapid industrialization, expanding healthcare infrastructure, and increasing investments in defense and aerospace across countries like China, India, Japan, and South Korea are fueling regional demand. The region also benefits from a growing base of local manufacturers and rising R&D activities in advanced materials, making it an attractive hub for UHMWPE production and consumption.

Meanwhile, Latin America and the Middle East & Africa present emerging markets with untapped potential, particularly in sectors like oil & gas, marine, and infrastructure. However, market growth in these regions is somewhat restrained by economic volatility, regulatory hurdles, and limited technological infrastructure. Nevertheless, as these regions continue to modernize and invest in high-performance materials, the UHMWPE market is expected to gain traction.

Ultra-high Molecular Weight Polyethylene Market Companies

- DSM-Firmenich

- Honeywell International Inc.

- Beijing Tongyizhong Specialty Technology & Development Co., Ltd.

- Dongyang MFG Co., Ltd.

- Sixty Sci-Tech Co., Ltd.

- DuPont

- Apex Polymers

- Avient Corporation

- Celanese Corporation

- JP FIBRES

Ultra-high Molecular Weight Polyethylene Market Recent Development

- In June 2022, Repsol invested €105 million to build the new ultra-high molecular weight polyethylene (UHMWPE) plant at its Industrial Site in Puertollano. The plant, scheduled to start up at the end of 2024, will have an annual manufacturing capacity of up to 15 kt.

(Source: https://www.repsol.com)

Segments Covered in the Report

By Form

- Sheets & Films

- Rods & Tubes

- Fibers

- Tapes

- Others

By End User

- Automotive

- Aerospace & Defense

- Medical

- Chemicals

- Electronics

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- MEA

Also Read: Transcranial Magnetic Stimulation System Market

Source: https://www.precedenceresearch.com/ultra-high-molecular-weight-polyethylene-market

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com|+1 804 441 9344