Background & Innovation

-

Challenge in Conventional Proppants:

Traditional frac sand tends to settle quickly in fractures due to higher specific gravity, leaving large sections unpropped. Resin-coated or ceramic proppants provide more strength, but they are heavier, costlier, and environmentally taxing. -

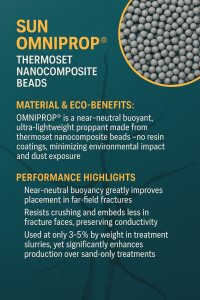

Solution – OMNIPROP®:

SUN Specialty Products developed OMNIPROP®, a thermoset nanocomposite bead engineered as an ultra-lightweight proppant (ULWP). Unlike resin-coated sands, OMNIPROP® is inherently lightweight, does not rely on coatings, and is non-toxic, dust-minimized, and eco-conscious.

Material & Environmental Benefits

-

Composition: Thermoset nanocomposite beads with near-neutral buoyancy (Apparent Specific Gravity ~1.06).

-

Eco-advantages:

-

Free of resin coatings → avoids dust hazards and resin degradation by-products.

-

Requires smaller volumes (3–5% by weight) compared to sand-only designs.

-

Recyclable handling and reduced transport intensity due to lightweight nature.

-

Performance Characteristics

-

Near-Neutral Buoyancy

-

Unlike sand (ASG ~2.65), OMNIPROP® remains suspended in slickwater and brine for longer periods.

-

Ensures better far-field transport, reaching distal portions of fractures where sand cannot.

-

-

Strength & Durability

-

High crush resistance, retaining fracture width at closure stresses.

-

Minimal embedment in fracture faces, preserving conductivity (tested up to ~12,500 psi and 325°F).

-

-

Conductivity Retention

-

Laboratory flow tests confirm superior conductivity retention compared to both sand and resin-coated proppants.

-

Field Application & Results

Trial Location:

-

Andrews County, Texas – San Andres Formation (carbonate reservoir).

Design & Mix:

-

Wells completed using slickwater + sand with 2–5% OMNIPROP® blended by weight.

-

Example: ~7,500 lb OMNIPROP® mixed with ~250,000 lb frac sand.

Results:

-

Fracture Area Coverage:

-

Sand-only: ~25% effective propped area.

-

Sand + OMNIPROP®: ~85% propped area.

-

-

Production Impact:

-

Average 30% increase in first-year cumulative oil production compared to offset sand-only wells.

-

In some wells, uplift exceeded 50,000 additional barrels within the first year.

-

-

Operational Ease:

-

Pumped as standard slurry with no special equipment required.

-

No handling or safety issues reported due to dustless, non-resin composition.

-

Read Also: Proppants Market

Comparative Advantages

| Factor | Sand | Resin-Coated Sand | Ceramics | OMNIPROP® ULWP |

|---|---|---|---|---|

| Density (ASG) | 2.65 | 2.5–2.6 | 3.2–3.6 | ~1.06 |

| Transportability | Poor (settles fast) | Moderate | Poor (heavy) | Excellent (buoyant) |

| Conductivity Retention | Low at closure stress | Moderate | High | High & stable |

| Environmental Impact | Dust exposure, mining intensity | Resin hazards | High energy intensity | Eco-friendly, dust-free |

| Cost Efficiency | Low upfront, poor recovery | Higher | Expensive | High ROI (3–5% blend boosts EUR) |

Industry Recognition

-

SPE Publications: Several technical papers presented at SPE Hydraulic Fracturing Technology Conference and referenced in Search.SPE.org, validating lab and field performance.

-

Independent Studies (AOGR): Field trial analysis documented improved recovery and fracture optimization in carbonate formations.

-

Adoption by Service Companies: Incorporated in treatments delivered by leading OFS players such as Baker Hughes and independent frac operators for unconventional plays.

Strategic Implications

-

Economic Uplift: Small additions (3–5% blend) deliver outsized ROI, making it a cost-effective option compared to full ceramic substitution.

-

Sustainability Positioning: Eco-conscious operators (especially in North America and Middle East) can align OMNIPROP® usage with ESG reporting and sustainability KPIs.

-

Future Expansion: AI-driven fracture modeling is being integrated to simulate OMNIPROP® transport in complex formations, optimizing blend ratios well-by-well.

SUN OMNIPROP® is a proven case of eco-friendly, ultra-lightweight proppant technology. Its buoyant nanocomposite design overcomes transport and conductivity issues of sand, while requiring minimal volumes to yield significant production uplift (≈30%+). This makes it a strong candidate for future sustainable fracturing operations, especially in unconventional and carbonate reservoirs.