Company Overview

Company Name: LG Energy Solution

Headquarters: Seoul, South Korea

Offering: NCMA (Nickel-Cobalt-Manganese-Aluminum) high-nickel cathode materials for electric vehicles

LG Energy Solution (LGES) is one of the world’s leading energy storage and battery manufacturers, known for pioneering next-generation lithium-ion battery technologies for electric vehicles (EVs), energy storage systems (ESS), and consumer electronics. As a spin-off from LG Chem, LG Energy Solution has established a strong presence across North America, Europe, and Asia through strategic partnerships with major automotive OEMs including General Motors (GM), Hyundai, Stellantis, and Honda.

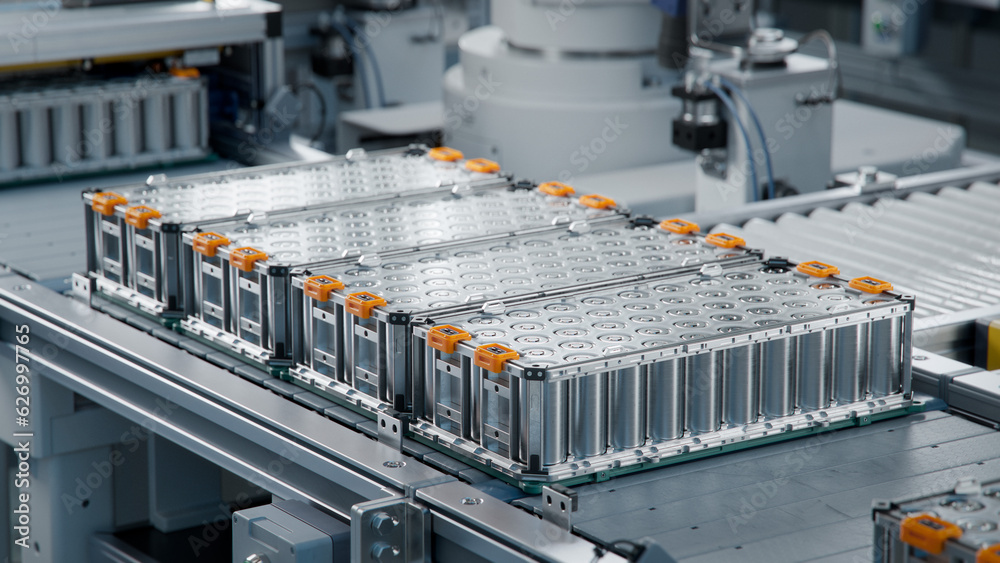

In 2025, LG Energy Solution took a significant leap forward by expanding its high-nickel NCMA cathode production capacity to meet surging demand for high-energy-density batteries used in long-range electric vehicles. This strategic move was part of its broader initiative to lead the transition toward cobalt-reduced and high-performance battery materials.

Case Study

As global electric vehicle sales continued to surge in 2025, automakers increasingly sought battery solutions that offered greater energy density, safety, and cost efficiency. To stay ahead of this trend, LG Energy Solution announced a major expansion of its NCMA (Nickel-Cobalt-Manganese-Aluminum) cathode production line at its Ochang facility in South Korea.

The upgraded plant was designed to produce next-generation cathode materials with a nickel composition of 90%, marking a substantial shift toward cobalt reduction — one of the key cost and sustainability challenges in lithium-ion battery manufacturing. Traditionally, cobalt has been used to stabilize cathode structures, but its scarcity and price volatility have created long-term supply risks.

By introducing aluminum as a stabilizing component, LG Energy Solution achieved improved thermal and structural integrity even at high nickel concentrations. The inclusion of aluminum also enhanced conductivity and reduced the rate of structural degradation during charge-discharge cycles.

This advanced NCMA cathode chemistry represented a critical evolution from the earlier NCM811 (80% nickel, 10% cobalt, 10% manganese) composition, providing higher energy density, improved heat resistance, and lower dependency on expensive cobalt materials.

The company’s R&D division worked closely with GM’s Ultium platform engineers and Hyundai’s E-GMP architecture team to integrate these new cathode materials into their next-generation battery cells. This collaboration ensured that cell design, form factor, and thermal management systems were optimized for maximum performance.

Outcome: Performance and Efficiency Gains

The deployment of LG’s NCMA cathode technology in EV battery cells led to an 8% improvement in driving range and a 12% reduction in material cost per kWh compared to previous-generation NCM batteries.

This achievement translated directly into tangible benefits for LG’s automotive partners. Vehicles powered by LG’s high-nickel batteries could travel longer distances on a single charge, improving consumer confidence and supporting the global push toward EV adoption.

Additionally, the enhanced cathode chemistry reduced the overall weight of the battery pack by around 5%, further contributing to energy efficiency and improved vehicle performance.

From a cost perspective, the reduced cobalt dependency and optimized production processes helped LG Energy Solution deliver a more competitive price structure to OEMs. This allowed automakers to reduce EV production costs while maintaining high energy density — a critical factor in making EVs more affordable and accessible to mainstream buyers.

Protectional: Ensuring Safety and Durability

One of the major challenges with high-nickel cathode materials is their tendency to form microcracks and experience thermal degradation over repeated charge cycles. LG Energy Solution addressed these issues through several protective innovations.

Firstly, the company employed advanced surface coating technology, applying nanoscale protective layers to prevent unwanted reactions between the cathode surface and the electrolyte. This minimized gas generation and prevented structural damage that could lead to performance loss or thermal runaway.

Secondly, LG implemented microstructure optimization at the particle level. By carefully controlling the morphology and crystalline structure of nickel-rich cathodes, the company reduced internal stress during cycling, extending the battery’s lifespan and maintaining capacity retention over thousands of cycles.

Thirdly, the addition of aluminum to the NCMA chemistry not only stabilized the cathode but also improved thermal conductivity, ensuring better heat dissipation during high-power operations such as fast charging.

Collectively, these protective measures enhanced both the safety and durability of LG’s high-nickel batteries, making them suitable for long-range EVs operating under diverse climate and usage conditions.

Impact on the Market

The successful commercialization of LG Energy Solution’s high-nickel NCMA cathodes had a significant impact on the global EV battery market.

-

Industry Leadership:

LG Energy Solution solidified its position as a top-three global supplier of advanced EV batteries, alongside CATL and Panasonic. Its NCMA technology gave it a competitive advantage in long-range and performance-oriented vehicle segments. -

OEM Partnerships Strengthened:

Major automotive partners — including GM and Hyundai — expanded their collaboration with LGES, signing multi-year contracts for battery supply. These partnerships enabled large-scale integration of NCMA-based cells into mass-market EVs, helping accelerate electrification across North America and Asia. -

Sustainability and ESG Goals:

The reduction in cobalt usage contributed to LG’s sustainability goals by minimizing reliance on conflict minerals. This move also aligned with global ESG standards, making LG Energy Solution a preferred partner for automakers committed to ethical and sustainable sourcing. -

Global Adoption of High-Nickel Batteries:

The success of LG’s NCMA technology spurred wider industry adoption of high-nickel formulations across the supply chain. Other manufacturers began developing similar chemistries to keep pace with performance and cost improvements achieved by LGES.

Overall, this innovation marked a major step toward achieving the energy density and cost targets required for EVs to compete directly with internal combustion engine vehicles.

Financial After Implementation

Following the expansion and deployment of its NCMA cathode materials, LG Energy Solution reported robust financial growth in 2025.

-

Revenue Growth: The company recorded a 9% increase in quarterly battery revenue, driven primarily by growing EV battery demand and improved production efficiency.

-

New Supply Contracts: LGES secured multi-year supply agreements with GM, Hyundai, and other OEMs valued at over USD 5.2 billion, ensuring stable order pipelines through 2028.

-

Operational Efficiency: The introduction of automated cathode production lines and advanced material sourcing strategies reduced production costs by approximately 10%, enhancing overall profit margins.

-

Investment Returns: The Ochang expansion, completed at a cost of roughly USD 800 million, is projected to deliver full ROI within 3.5 years through consistent output and strategic partnerships.

Additionally, the company’s improved energy density and reliability metrics strengthened its brand reputation and attracted new ESS (energy storage system) clients in Europe and North America.

Conclusion

LG Energy Solution’s success with NCMA high-nickel cathode materials in 2025 highlights a pivotal moment in the evolution of EV battery technology. By combining high nickel content, reduced cobalt dependency, and enhanced safety mechanisms, LG achieved a balanced formula that advanced both performance and sustainability.

The expansion of its Ochang plant not only met the surging global demand for long-range EV batteries but also reinforced LG’s leadership in the next generation of lithium-ion chemistry. The company’s commitment to innovation, strategic partnerships, and responsible sourcing continues to set benchmarks for the global battery industry.

Ultimately, this case underscores how technological refinement and material innovation can simultaneously drive commercial success, environmental responsibility, and market transformation in the rapidly growing electric mobility sector.

Dive into the full analysis here: https://www.precedenceresearch.com/high-nickel-cathode-materials-market