A New Era for the 3D Printing Materials and Equipment Market

The 3D printing materials and equipment market is experiencing a transformative leap in 2025, fueled by developments in aerospace, sports technology, and industrial prototyping. From space missions to golf clubs and semiconductor prototyping, innovation is rapidly expanding the role of additive manufacturing across sectors.

Three recent developments showcase this trend:

-

Peak Technology’s acquisition of Jinxbot 3D Printing

-

Airbus’ delivery of a 3D metal printer to the International Space Station

-

Cobra Golf’s release of 3D printed King Tour Irons

These case studies reflect how the market is shifting towards advanced use cases, driving demand for specialized materials, high-precision equipment, and integrated design solutions.

Peak Technology Acquires Jinxbot 3D Printing: Speed and Complexity for Industrial Innovation

In May 2025, Peak Technology announced the acquisition of Jinxbot 3D Printing, a strategic move aimed at accelerating high-performance prototyping for critical industries like biomedical, aerospace, semiconductors, and deep tech.

Why This Matters

This acquisition highlights a growing demand for fast-turnaround, high-complexity 3D printed prototypes. Companies in technically demanding industries are increasingly turning to additive manufacturing to shorten product development cycles, lower costs, and test innovations faster.

By combining Jinxbot’s rapid-printing capabilities with Peak Technology’s application-focused engineering, the move reflects a shift toward integrated manufacturing ecosystems where materials, design, and production are tightly interwoven.

Airbus Sends 3D Metal Printer to the ISS: Pioneering In-Space Manufacturing

In March 2025, the space technology division of Airbus achieved a significant milestone by delivering a metal 3D printer to the European Space Agency (ESA). It was later installed on the International Space Station (ISS) by astronaut Andreas Mogensen, marking a critical step in in-space manufacturing.

The Significance

For the first time, astronauts can use additive manufacturing to produce metal parts directly in orbit, freeing up storage space and reducing dependence on Earth-bound logistics. The system has already produced four metal components, showcasing its potential to support long-duration space missions.

This development highlights the increasing sophistication of 3D printing equipment, especially in extreme environments. The need for durable, lightweight, and high-performance materials is growing—creating new opportunities for material innovation.

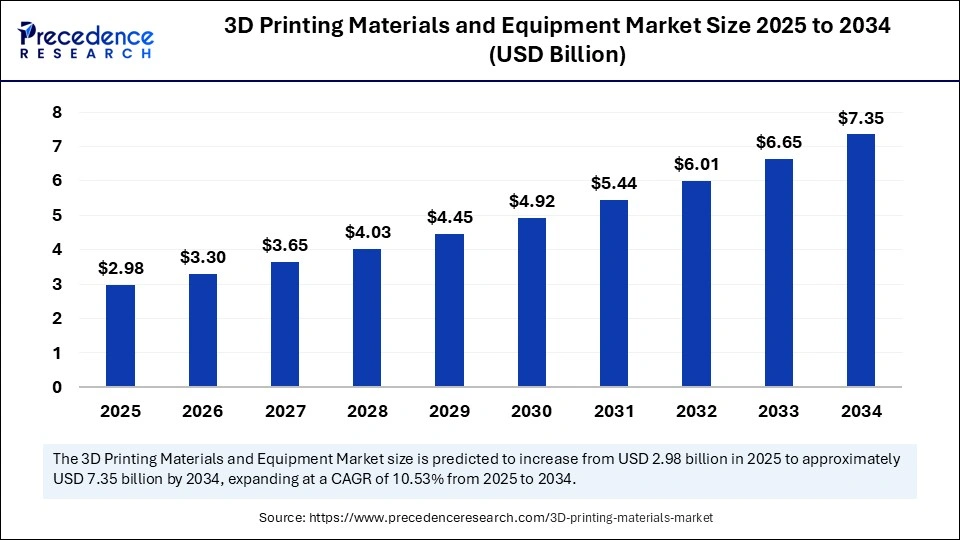

The global 3D printing materials and equipment market size is estimated to hit around USD 7.35 billion by 2034

Cobra Golf’s 3D Printed Irons: Additive Manufacturing Meets Athletic Performance

In February 2025, Cobra Golf, a Californian sports equipment brand, launched its 3D printed King Tour Irons, designed with Direct Metal Laser Sintering (DMLS). These clubs feature a lattice structure that cuts down weight by 33%, enhancing swing speed, balance, and playability.

Why This Is a Big Deal

Sports and consumer products are becoming a frontier for 3D printing. Cobra Golf’s use of DMLS a technique commonly associated with industrial and aerospace components shows how advanced equipment is trickling down into consumer goods.

The result? Equipment tailored to high-performance needs, backed by rapid customization and superior material properties.

Market Trends Shaping the 3D Printing Materials and Equipment Market in 2025

1. Cross-Industry Adoption

The lines are blurring between sectors — from outer space to elite sports and medical devices, additive manufacturing is finding utility across unexpected verticals.

2. Advanced Metal Printing

Technologies like DMLS and SLM (Selective Laser Melting) are enabling new levels of complexity, thermal tolerance, and structural integrity, particularly in aerospace and defense.

3. Demand for High-Performance Materials

As 3D printing applications grow more demanding, so does the need for materials like titanium alloys, carbon fiber composites, and biocompatible polymers.

4. Hybrid Manufacturing Approaches

Mergers and acquisitions—like Peak and Jinxbot—illustrate how companies are creating vertically integrated workflows that combine design, material science, and on-demand production.

Challenges Ahead for the 3D Printing Materials and Equipment Market

While the market is booming, some hurdles remain:

-

Material Costs: High-quality printing metals and engineered polymers are still expensive.

-

Regulatory Compliance: Especially in biomedical and aerospace applications, certification can delay time to market.

-

Equipment Investment: Advanced printers come with a steep price tag and require skilled labor.

-

Supply Chain Complexity: Managing diverse materials and proprietary designs calls for smart inventory solutions and digital workflows.

Opportunities for Stakeholders and Innovators

Despite the challenges, 2025 opens new doors for growth:

-

Expansion into Space and Defense Sectors

-

Mass Customization in Sports, Wearables, and Healthcare

-

On-demand Manufacturing for Remote Locations

-

Collaborative Platforms for Material R&D

Conclusion: The 3D Printing Materials and Equipment Market is Just Getting Started

As 2025 unfolds, the 3D printing materials and equipment market continues to push technological and sectoral boundaries. Whether it’s Peak Technology accelerating innovation cycles, Airbus enabling off-Earth fabrication, or Cobra Golf redefining athletic equipment, the message is clear:

Additive manufacturing is no longer a niche it’s an essential pillar of modern production.

From precision to personalization, the evolution of materials and equipment is reshaping what’s possible. Organizations that invest early in R&D, materials innovation, and hybrid design systems will be the ones to define the next decade of growth.

Also Read: 3D Printing Materials and Equipment Market

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6204

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com|+1 804 441 9344