Heat-Shrink Tubing Market Key Points

-

North America accounted for the largest revenue share of 36% in 2024.

-

The Asia Pacific region is anticipated to grow at the fastest CAGR from 2025 to 2034.

-

Based on application, the automotive segment led the global market with the highest revenue share in 2024.

-

The electrical and electronics segment is projected to register the fastest CAGR between 2025 and 2034.

-

By material, the polyolefin segment contributed the largest share of revenue in 2024.

-

The polyvinyl chloride segment is expected to witness the highest growth rate over the forecast period.

-

In terms of wall thickness, the thin wall segment held the major revenue share in 2024.

-

The medium wall segment is forecasted to grow at the fastest CAGR from 2025 to 2034.

-

By shrink ratio, the 2:1 segment dominated the global heat shrink tubing market in 2024.

-

The 3:1 segment is anticipated to grow at the highest CAGR during the forecast period.

-

Regarding certification, the UL segment generated the largest revenue share in 2024.

-

The ISO segment is projected to expand at the fastest CAGR from 2025 to 2034.

What Is Heat-Shrink Tubing and What Is It Used For?

Heat-shrink tubing is a specialized plastic tube that shrinks in diameter when heated, providing a tight, protective covering over wires, cables, and connectors. It is commonly made from materials like polyolefin, PVC, or fluoropolymers, which offer excellent insulation, chemical resistance, and mechanical strength. Heat-shrink tubing is widely used in electrical, automotive, aerospace, and telecommunications industries to protect components from moisture, abrasion, dust, and environmental damage.

How Does Heat-Shrink Tubing Work and Why Is It Beneficial?

Heat-shrink tubing is easy to apply: once placed over the target area, it is heated using a heat gun or other source, causing the tubing to contract and form a snug, secure fit. This not only provides electrical insulation and mechanical support but also helps with strain relief and wire bundling. Available in various sizes, colors, and shrink ratios, heat-shrink tubing is a cost-effective and versatile solution for improving the safety, durability, and organization of electrical systems.

How is AI Contributing to Innovation in the Heat-Shrink Tubing Market?

AI is enhancing the heat-shrink tubing market by streamlining the manufacturing process and improving product quality. Through machine learning algorithms, manufacturers can monitor production in real-time, detect defects early, and predict maintenance needs for machinery, thereby reducing downtime and waste. This leads to higher efficiency and more consistent product output.

Additionally, AI aids in customizing heat-shrink tubing solutions based on application-specific requirements. By analyzing customer usage data and environmental factors, AI can help design tubing with optimal thermal, electrical, and mechanical properties. This personalized approach is boosting the adoption of advanced heat-shrink tubing across sectors like automotive, aerospace, and electronics.

Growth Factors of the Heat-Shrink Tubing Market

The heat-shrink tubing market is witnessing strong growth due to the rising demand in key sectors such as automotive, electrical and electronics, telecom, and renewable energy. Increasing use in cable insulation, wire bundling, and environmental protection, especially in the automotive and telecom industries, is a major growth driver. Additionally, advancements in tubing materials—like polyolefin—and the push for flame-retardant, UV-resistant, and high-shrink-ratio tubing are expanding usage across diverse applications, including medical devices and industrial machinery.

Further supporting growth is the increasing emphasis on safety standards, sustainability, and energy efficiency. Governments and industries are adopting reliable insulation solutions to meet strict regulations, while regional markets like Asia-Pacific are expanding rapidly due to infrastructure development and industrialization. Customization trends, coupled with investments in smart manufacturing and material innovation, are expected to drive the future of the heat-shrink tubing industry.

Market Scope

| Report Coverage | Details |

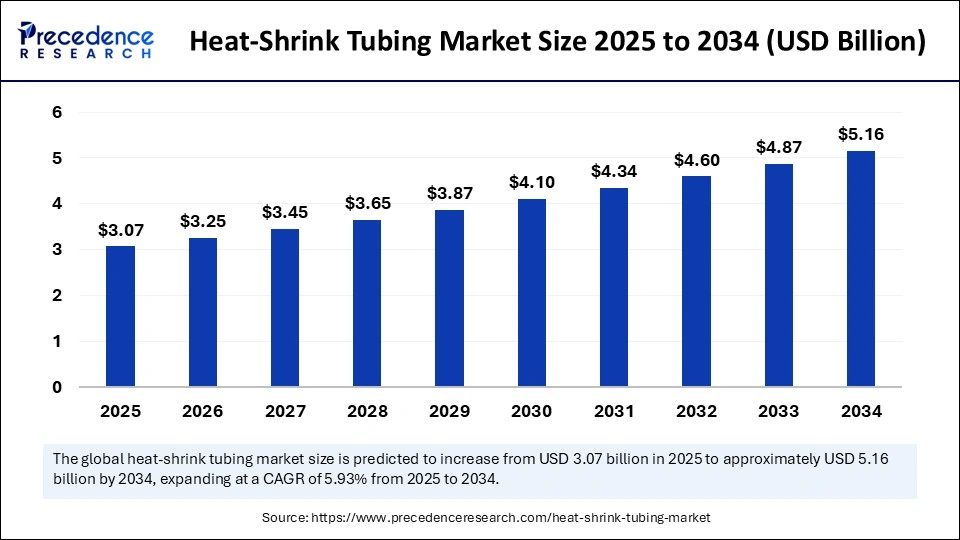

| Market Size by 2034 | USD 5.16 Billion |

| Market Size in 2025 | USD 3.07 Billion |

| Market Size in 2024 | USD 2.90 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.93% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Application, Material, Wall Thickness, Ratio, Certification, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Heat-Shrink Tubing Market Drivers

The heat-shrink tubing market is primarily driven by growing demand across automotive, electrical, and telecommunications sectors for insulation, protection, and sealing of wires and cables. The increasing use of electric vehicles (EVs) and the expansion of power distribution networks have fueled the need for reliable insulation materials. Additionally, the push for safety and efficiency in electrical systems supports the widespread use of heat-shrink tubing.

Opportunities in the Market

There are rising opportunities in renewable energy and aerospace industries, where heat-shrink tubing is used to safeguard sensitive components under extreme conditions. The miniaturization of electronics and the proliferation of connected devices (IoT) also create new needs for compact and durable insulation solutions. Furthermore, advancements in materials, such as dual-wall and radiation-crosslinked tubing, are expanding application possibilities.

Challenges in the Market

Challenges include fluctuating raw material prices and the need for high-performance products tailored to specific environments, which can increase costs. Compatibility with newer electronic components and maintaining quality under harsh conditions also pose technical hurdles. Additionally, market penetration in cost-sensitive regions may be restricted due to higher product prices compared to traditional insulation methods.

Regional Outlook

North America holds a significant share of the heat-shrink tubing market, supported by robust demand from automotive, aerospace, and defense sectors. Europe follows closely, driven by stringent safety standards and renewable energy developments. Asia Pacific is expected to witness the fastest growth due to rapid industrialization, increasing electrical infrastructure projects, and rising EV production in countries like China, Japan, and India.

Heat-Shrink Tubing Market Companies

- Panduit

- Alpha Wire

- Sumitomo Electric Industries

- ElectriFlex Company

- Caplugs

- TE Connectivity Ltd.

- DENSIT

- Mundial

- Antronix

- AutomationDirect

- Hellermann Tyton

- nVent Electric

- Garland Industries

- Canusa

- 3M

- Iljin Electric

Segments covered in the report

By Application

- Automotive

- Electrical and Electronics

- Telecommunications

- Military and Aerospace

- Medical and Healthcare

By Material

- Polyolefin

- Polyvinyl Chloride (PVC)

- Fluoropolymer

- Silicone

- Elastomer

By Wall Thickness

- Thin Wall

- Medium Wall

- Thick Wall

By Ratio

- 5:1

- 2:1

- 3:1

- 4:1

- 5:1

By Certification

- UL

- CSA

- RoHS

- REACH

- ISO

By Region

- North America

- Latin America

- Europe

- Asia-pacific

- Middle and East Africa

Also Read: Silicon Nitride Market

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6183

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com|+1 804 441 9344