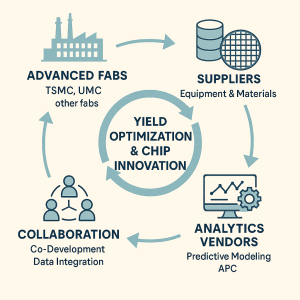

Taiwan has become the global hub for semiconductor manufacturing, driven largely by its highly integrated foundry ecosystem. Unlike fragmented models in other regions, Taiwan’s approach thrives on tight collaboration between advanced fabs, upstream suppliers, and analytics vendors. This collaborative strategy has created a self-reinforcing cycle of yield improvement, predictive optimization, and rapid innovation, enabling Taiwan to consistently lead in advanced process technologies.

The Core of the Ecosystem: Foundries and Advanced Fabs

-

TSMC as the anchor: Taiwan Semiconductor Manufacturing Company (TSMC) stands as the centerpiece, pioneering cutting-edge nodes (e.g., 7nm, 5nm, and 3nm) that drive the global semiconductor roadmap.

-

Clustered expertise: Other foundries and specialty fabs—UMC, Vanguard, and PSMC—contribute to a balanced ecosystem that serves both high-volume logic and specialty applications.

-

Proximity advantage: With fabs concentrated in hubs like Hsinchu Science Park and Southern Taiwan Science Park, collaboration and rapid iteration cycles become seamless.

Read Also: Analog Semiconductor Market

Supplier and Partner Integration

Taiwan’s foundry ecosystem is not just about fabs—it includes equipment suppliers, material providers, and metrology specialists:

-

Equipment & materials: Suppliers of photolithography resists, specialty chemicals, and wafer substrates are embedded in the supply chain, ensuring quick feedback loops.

-

EDA & analytics vendors: Partnerships with firms like Cadence, Synopsys, and smaller AI-driven analytics vendors strengthen process control through real-time data integration.

-

Co-development culture: Unlike more siloed ecosystems elsewhere, Taiwan fosters co-innovation—vendors often test solutions directly inside fabs for faster adoption.

Advanced Analytics and Process Control

The key differentiator in Taiwan’s ecosystem is how it uses predictive modeling and advanced process control (APC) to achieve yield leadership:

-

Predictive modeling: AI and ML models forecast defectivity trends, wafer uniformity issues, and potential bottlenecks before they impact production.

-

APC frameworks: Real-time feedback systems adjust process variables at the tool level, minimizing variability across wafers and lots.

-

Data-driven fabs: With integrated sensors and data pipelines, Taiwanese fabs run thousands of control parameters simultaneously, giving them unmatched first-pass success rates compared to global peers.

Yield Optimization as a Competitive Advantage

-

First-pass yield (FPY) excellence: Taiwan fabs consistently achieve higher FPY rates—meaning chips meet specifications in the first manufacturing cycle without costly rework.

-

Cost leadership: Higher yields translate into lower cost per chip, making Taiwan the go-to choice for fabless companies worldwide.

-

Innovation speed: With reduced rework cycles, engineers can focus more on R&D and next-node innovation rather than firefighting yield issues.

Ecosystem-Wide Collaboration Model

The success lies in ecosystem synergy:

-

Government support: Policies from Taiwan’s Ministry of Economic Affairs and Science Parks Administration provide infrastructure, R&D grants, and favorable regulations.

-

Academia-industry link: Universities collaborate on semiconductor research, feeding talent and new algorithms into fabs.

-

Open innovation: Cross-company collaborations allow suppliers, foundries, and fabless firms to jointly solve yield and scaling challenges.

Global Impact and Competitive Benchmark

-

Technology leadership: Taiwan set the pace for advanced nodes, from 10nm down to 3nm, and is shaping the transition to 2nm.

-

Benchmarking vs. global peers: U.S., Japan, and Korea also have strong ecosystems, but Taiwan outpaces them in ecosystem integration and agility.

-

Resilience: Even amid geopolitical tensions, Taiwan’s foundries are considered irreplaceable due to their deep process expertise and integrated supply ecosystem.

Future Outlook: Beyond Manufacturing

-

Smart manufacturing & AI integration: The next frontier involves digital twins and AI-driven fabs for fully autonomous manufacturing.

-

Green fabs: With sustainability becoming critical, Taiwan’s fabs are investing in energy efficiency, water recycling, and carbon reduction technologies.

-

Global partnerships: Expansion plans in the U.S. (Arizona), Japan (Kumamoto), and Europe highlight Taiwan’s growing global role while still keeping the home ecosystem as the innovation hub.

Key Lessons from Taiwan’s Foundry Ecosystem

-

Collaboration beats competition within an ecosystem—yielding higher efficiencies.

-

Data-driven manufacturing with predictive modeling and APC can redefine yield leadership.

-

Proximity and clustering amplify speed, trust, and innovation cycles.

-

Government and academia integration ensures continuous talent and technology pipelines.

In essence, Taiwan’s foundry ecosystem demonstrates that success in semiconductors is not just about building advanced fabs—it’s about creating a tightly integrated, data-driven, collaborative environment where every player, from suppliers to analytics vendors, contributes to innovation and yield optimization. This model has set the global benchmark for semiconductor manufacturing excellence.