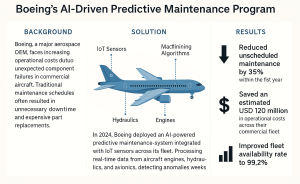

Boeing, one of the largest aerospace OEMs globally, manages a vast fleet of commercial aircraft that serve airlines worldwide. While the company’s aircraft are built to high safety and engineering standards, unexpected component failures particularly in engines, hydraulics, and avionics had become a major cost and operational challenge.

Traditional time-based maintenance schedules meant that parts were replaced or inspected at fixed intervals, regardless of their actual condition. This led to two persistent issues:

-

Unnecessary downtime, where aircraft were grounded for checks even when no real issues existed.

-

Costly emergency repairs, where components failed earlier than expected, disrupting flight schedules and damaging customer trust.

With global air traffic expanding and airlines under pressure to increase fleet utilization, Boeing recognized that improving maintenance precision could deliver significant financial and operational benefits—not only for its own operations but also as a value-added service to customers.

Solution

In 2024, Boeing rolled out an AI-powered Predictive Maintenance System acro

ss its commercial fleet, integrating IoT-enabled sensors into critical aircraft systems such as:

-

Engines – temperature, vibration, and pressure sensors.

-

Hydraulic systems – fluid pressure, leak detection, and actuator performance.

-

Avionics – real-time monitoring of navigation and control systems.

The AI system’s core was built on machine learning algorithms trained with historical maintenance records, real-time flight data, and environmental factors such as temperature, altitude, and humidity. The model continuously refined its predictions by learning from every new data point received.

Key components of the solution included:

-

Edge data processing for real-time anomaly detection during flights.

-

Cloud-based AI models for deeper trend analysis and fleet-wide insights.

-

Predictive analytics dashboards for maintenance teams, highlighting priority inspections and estimated time-to-failure for each component.

The integration was done in partnership with Boeing AnalytX (the company’s data analytics division) and external AI providers specializing in aerospace-grade machine learning solutions.

Implementation Process

-

Pilot Phase: The system was first tested on a small subset of Boeing 787 Dreamliners over a six-month period, covering both short-haul and long-haul routes.

-

Algorithm Training: Data from over 200,000 flight hours was used to train predictive models, ensuring high accuracy in fault detection.

-

Full Fleet Deployment: Following successful trials, the AI system was installed across Boeing’s in-service fleet, with real-time monitoring available to airline clients through an integrated platform.

-

Staff Training: Airline maintenance crews received AI-assisted maintenance training, enabling them to act on predictive alerts with precision.

Results (First-Year Impact)

The adoption of AI-driven predictive maintenance delivered transformative results:

-

35% reduction in unscheduled maintenance events, allowing airlines to plan repairs well in advance.

-

USD 120 million saved in operational costs across Boeing’s commercial fleet in the first year alone.

-

Fleet availability increased to 99.2%, significantly improving airline scheduling and reducing flight cancellations.

-

Extended component lifespan by up to 20%, thanks to timely interventions before wear escalated.

-

Improved customer satisfaction among airline operators due to reduced delays and cancellations.

Strategic Benefits

Beyond cost savings, this initiative positioned Boeing as a leader in AI-driven aerospace solutions, creating a new competitive advantage:

-

Airlines using Boeing aircraft gained access to real-time health monitoring as part of their service package.

-

Boeing deepened customer relationships by offering value-added digital services, not just physical aircraft.

-

The system provided Boeing with long-term operational data, helping refine aircraft designs for future models.

Market Insight Connection

This case study directly reflects:

-

Predictive Maintenance Dominance: The predictive maintenance sub-segment accounted for 26.8% of the aerospace AI market in 2024, underlining its critical role in cutting operational costs and improving safety.

-

Commercial Aircraft Leadership: The commercial aircraft platform segment held 33.7% market share in 2024, showing the strong adoption of AI solutions in passenger aviation.

-

Machine Learning Strength: Machine learning technology, with a 41.2% market share, powers most predictive analytics in aerospace, as evidenced by Boeing’s successful deployment.