Precipitated Calcium Carbonate Market Key Points

-

Asia Pacific dominated the market, accounting for a 45% share in 2024.

-

North America is projected to record the fastest CAGR during the forecast period.

-

By application type, the paper segment held the largest market share in 2024.

-

The plastics segment is expected to be the fastest-growing application during the forecast years.

-

By production process, the carbonation process accounted for the largest share of 70% in 2024.

-

The hydrochloric acid method is projected to grow at a significant CAGR between 2025 and 2034.

-

By form, the powder segment led the market with a 55% share in 2024.

-

The slurry segment is anticipated to grow at a remarkable CAGR during the forecast period.

-

By grade, the industrial grade segment held the major market share of 60% in 2024.

-

The pharmaceutical grade segment is projected to expand at a notable CAGR from 2025 to 2034.

Precipitated Calcium Carbonate Market Growth Factors

The primary factors fueling the growth of the PCC market include the growing demand from the paper and packaging industries, where PCC is used to improve the brightness, opacity, and printability of paper. Additionally, the pharmaceutical industry relies heavily on PCC for use in tablet formulations, antacids, and dietary supplements due to its biocompatibility and safety profile.

The food and beverage sector also employs PCC as a calcium fortifier and food additive. Furthermore, the increasing use of PCC in cosmetic products for enhancing texture and consistency, along with its application in the construction industry for paints, coatings, and adhesives, supports robust market growth across sectors.

AI Role in the Precipitated Calcium Carbonate Market

Artificial Intelligence (AI) is beginning to play a transformative role in the PCC market, particularly in manufacturing and quality control processes. AI-driven systems are being used to optimize key production parameters such as temperature control, carbonation rates, and crystal morphology, leading to improved product consistency and reduced waste.

Machine learning algorithms enable predictive maintenance of equipment, minimizing downtime and enhancing operational efficiency. In R&D, AI aids in simulating chemical reactions and optimizing formulations to develop new grades of PCC tailored for specialized industrial applications. The integration of AI across production lines not only reduces operational costs but also elevates the quality and scalability of PCC manufacturing.

Precipitated Calcium Carbonate Market Scope

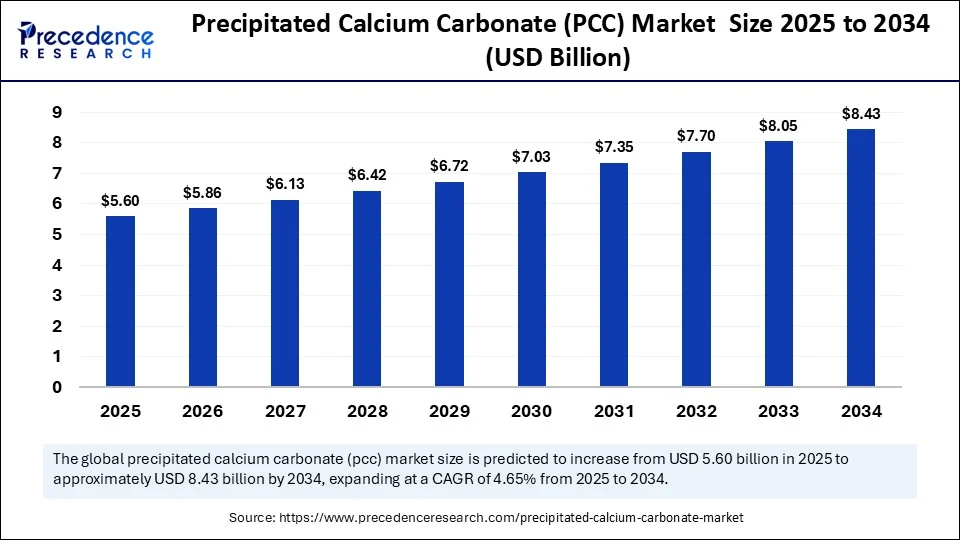

| Report Coverage | Details |

| Market Size by 2034 | USD 8.43 Billion |

| Market Size in 2025 | USD 5.6 Billion |

| Market Size in 2024 | USD 5.35 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.65% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Application, Production Process, Form, Grade, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Drivers

Several market drivers are propelling the PCC industry forward. The booming demand for sustainable and lightweight materials in packaging and plastic manufacturing is creating new avenues for PCC adoption. In the construction industry, PCC is favored for its reinforcement properties and is used extensively in cement, concrete, and sealants. The growing awareness of nutritional supplements and the need for calcium-rich diets are pushing the pharmaceutical and food industries to integrate PCC in their product lines.

Moreover, the shift toward eco-friendly manufacturing practices and the increasing focus on product quality and regulatory compliance are encouraging industries to adopt PCC as a safer and more sustainable alternative to other mineral fillers.

Opportunities

The PCC market presents numerous opportunities for innovation and expansion. One major opportunity lies in the development of nano-grade PCC, which offers enhanced properties such as higher surface area and improved dispersion in polymers and coatings. Emerging markets in Asia-Pacific, Latin America, and the Middle East are showing increased demand for PCC due to rapid industrialization, urban development, and infrastructure growth.

There is also a growing interest in bio-based and green manufacturing methods, where PCC production can be aligned with carbon capture and utilization technologies to support environmental sustainability. Additionally, expanding applications in medical devices, nutraceuticals, and high-performance polymers open new doors for market players.

Challenges

Despite the positive outlook, the PCC market faces several challenges. Price volatility of raw materials such as limestone and lime can significantly affect the cost structure of PCC production. Environmental regulations related to mining and emissions control may also pose compliance burdens for manufacturers.

Technical challenges such as maintaining consistent particle size and purity, especially in pharmaceutical and food-grade PCC, require significant investment in quality control and process optimization. Furthermore, competition from alternative fillers like ground calcium carbonate (GCC), kaolin, and talc can limit the growth potential in certain applications where cost sensitivity outweighs performance benefits.

Regional Outlook

Regionally, Asia-Pacific leads the PCC market and is expected to continue its dominance due to high demand from paper, packaging, plastics, and construction industries in countries like China, India, and Southeast Asia. The region benefits from abundant raw materials, growing industrial output, and supportive government policies promoting manufacturing growth.

North America holds a significant share, driven by the pharmaceutical, food, and packaging industries, along with stringent quality standards that favor the use of high-purity fillers like PCC. Europe remains a mature market with steady demand from the cosmetics and industrial coatings sectors, coupled with strong environmental regulations that encourage the use of sustainable materials.

Latin America, the Middle East, and Africa are emerging markets with growth potential supported by infrastructure development and increasing awareness of advanced material solutions.

Precipitated Calcium Carbonate Market Companies

- Imerys S.A.

- Omya AG

- Minerals Technologies Inc.

- Huber Engineered Materials (J.M. Huber Corporation)

- Mississippi Lime Company

- Schaefer Kalk GmbH & Co. KG

- Calcium Carbonate Co. Ltd. (Malaysia)

- Carmeuse

- Gulshan Polyols Ltd.

- Nordkalk Corporation

- Lhoist Group

Segments Covered in the Report

By Application

- Paper

- Coating

- Filling

- Plastics

- PVC

- Polypropylene (PP)

- Polyethylene (PE)

- Others

- Paints & Coatings

- Architectural

- Industrial

- Adhesives & Sealants

- Personal Care

- Toothpaste

- Skincare

- Pharmaceuticals

- Rubber

- Food & Beverages

- Anticaking Agent

- Fortification Agent

- Others

- Detergents

- Agriculture

By Production Process

- Carbonation Process

- Hydrochloric Acid Method

- Others

By Form

- Powder

- Slurry

- Granule

- Others

By Grade

- Industrial Grade

- Pharmaceutical Grade

- Food Grade

- Cosmetic Grade

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Read Also: Hydrogen Internal Combustion Engines Market

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com|+1 804 441 9344