3D Printing Materials and Equipment Market Key Points

-

North America accounted for the largest revenue share of 40% in the 3D printing materials market in 2024.

-

Asia Pacific is projected to grow at a significant CAGR from 2025 to 2034.

-

By material type, the metals segment led the market with the highest revenue share in 2024.

-

The plastics segment is expected to expand at the highest CAGR over the forecast period.

-

In terms of product, the fused deposition modeling (FDM) segment held the dominant market share in 2024.

-

The selective laser sintering (SLS) segment is anticipated to grow at the highest CAGR in the coming years.

-

By end-user, the industrial segment generated the largest revenue share in 2024.

-

The automotive segment is expected to register the fastest CAGR during the forecast period.

Overview of 3D Printing Materials and Equipment

3D printing materials and equipment form the backbone of additive manufacturing technologies used to create objects layer by layer from digital models. The equipment includes various types of 3D printers such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS) machines, each suited to different applications and material types. These machines are used across industries for prototyping, tooling, and final part production, ranging from consumer goods to aerospace components.

How Is AI Empowering the 3D Printing Materials & Equipment Market?

AI is significantly accelerating the development of new materials in the 3D printing industry by analyzing large material databases and optimizing formulations. Using data-driven algorithms, AI can recommend ideal combinations of materials and printing parameters—such as layer height, temperature, and material composition—to ensure high performance and manufacturability. This reduces the need for trial-and-error experimentation and enables faster qualification of advanced materials like smart alloys, bio-based polymers, and functional composites. Additionally, AI supports generative design, helping users—regardless of expertise—create optimized parts for specific performance goals.

On the equipment front, AI is enhancing print reliability, quality assurance, and operational efficiency. AI-driven computer vision systems monitor the printing process in real time, identifying and correcting defects like cracks, warping, or dimensional inaccuracies. These systems also enable predictive maintenance by analyzing machine usage patterns and detecting signs of wear, thus minimizing downtime. With the integration of cloud platforms and digital twins, AI-enabled 3D printing equipment supports flexible, scalable manufacturing—ideal for industries such as aerospace, healthcare, automotive, and construction.

3D Printing Materials and Equipment Market Growth Factors

-

Explosion in Industrial Adoption

Major industries—such as aerospace, automotive, healthcare, and consumer goods—are increasingly using 3D printing for prototyping, tooling, and production parts, driving demand for both materials and equipment. -

Advances in Material Innovation

Development of new polymers, photopolymers, metals, ceramics, composites, and biocompatible materials has broadened application scope, enabling complex, high-performance, and customized manufacturing. -

Customization & Design Freedom

The ability to create intricate geometries and personalized products—like medical implants or bespoke consumer items—offers manufacturers unparalleled flexibility and value. -

Cost and Time Efficiency

By eliminating tooling costs and accelerating production cycles, additive manufacturing reduces waste and speeds time-to-market, making the technology increasingly attractive. -

Shift Toward Sustainability

Additive processes reduce material waste and carbon emissions, while rising interest in recyclable and biodegradable materials strengthens the eco-friendly appeal. -

AI, Automation & Industry 4.0 Integration

Smart features like real-time monitoring, AI-driven print optimization, and automated workflows are improving efficiency, quality, and scalability in printing processes. -

Growth in Desktop & Distributed Manufacturing

Affordable desktop printers and distributed manufacturing networks are expanding adoption among SMEs, educational institutions, and prosumers, boosting materials and entry-level equipment sales. -

Regional Infrastructure Expansion

Rapid growth in regions like Asia-Pacific—driven by automotive, electronics, and construction sectors—is supporting strong investment in both materials and equipment.

Market Scope

| Report Coverage | Details |

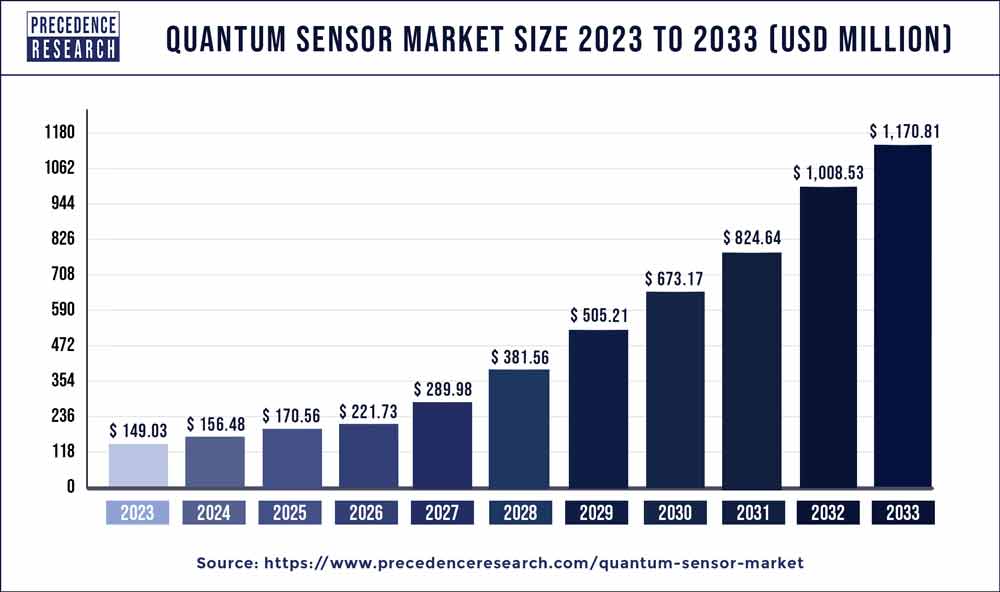

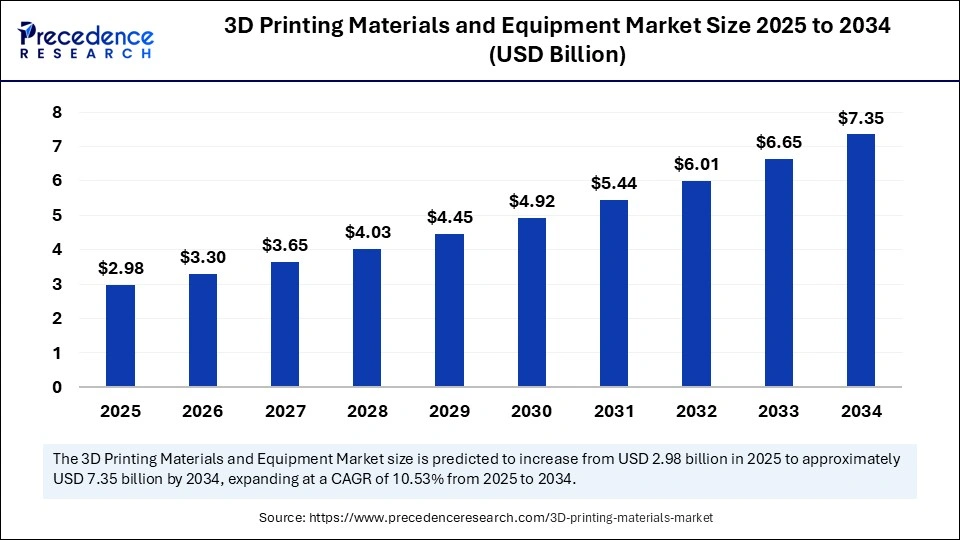

| Market Size by 2034 | USD 7.35 Billion |

| Market Size in 2025 | USD 2.98 Billion |

| Market Size in 2024 | USD 2.70 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 10.53% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material Type, Product, End-users, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Market Drivers

The 3D printing materials and equipment market is being driven by the increasing demand for rapid prototyping and advanced manufacturing solutions across multiple industries such as aerospace, automotive, healthcare, consumer electronics, and construction. Companies are adopting 3D printing to enhance design flexibility, reduce time-to-market, and minimize waste in the production process. Advancements in printing technologies—such as selective laser sintering (SLS), fused deposition modeling (FDM), and stereolithography (SLA)—have significantly improved the precision, speed, and scalability of 3D printing processes.

In parallel, the evolution of a wide range of high-performance materials including metals, polymers, ceramics, and composites has expanded the scope of application from simple prototypes to functional end-use products. Additionally, the increasing affordability of desktop 3D printers and materials is supporting adoption among small businesses, educational institutions, and hobbyists. The shift toward Industry 4.0 and smart manufacturing is also accelerating the demand for customizable and decentralized production solutions enabled by 3D printing.

Opportunities

The market offers significant growth opportunities in the development of innovative and sustainable 3D printing materials such as bio-based polymers, recyclable filaments, and biodegradable composites. As environmental concerns grow, there is a strong demand for greener alternatives that reduce waste and carbon footprints. Moreover, the healthcare sector presents vast opportunities for personalized medical solutions including prosthetics, implants, and dental devices, with bioprinting emerging as a transformative technology for tissue engineering and regenerative medicine.

Another promising area is the construction industry, where large-scale 3D printers are being used to build affordable housing and complex architectural structures quickly and cost-effectively. In aerospace and defense, the ability to create lightweight yet strong components using advanced materials is driving innovation in aircraft and spacecraft design. Furthermore, as 3D printing increasingly integrates with AI and IoT, smart printers with predictive maintenance and autonomous calibration will unlock new capabilities and efficiencies.

Challenges

Despite strong momentum, the market faces several challenges that could hinder widespread adoption. High initial investment costs for industrial-grade 3D printers and materials remain a major barrier for small and medium enterprises (SMEs). Additionally, the lack of standardized materials and regulatory frameworks for quality control and safety poses a significant challenge, particularly in critical applications like aerospace and medical devices. Material limitations, such as restricted mechanical properties or durability in certain conditions, can limit the use of 3D printing for some end-use parts.

Intellectual property (IP) protection is another key concern, as digital design files can be easily copied or modified. There is also a shortage of skilled professionals with expertise in additive manufacturing technologies, materials science, and design optimization, which slows down adoption in traditional industries. Moreover, inconsistent printing results and post-processing requirements add to the complexity and cost of integrating 3D printing into existing production workflows.

Regional Outlook

North America currently leads the 3D printing materials and equipment market, supported by strong R&D investment, a well-established industrial base, and early adoption of advanced manufacturing technologies in the U.S. and Canada. Europe follows closely, with countries like Germany, the UK, and the Netherlands at the forefront due to their automotive, aerospace, and engineering sectors’ interest in additive manufacturing.

The Asia-Pacific region is witnessing the fastest growth, driven by rapid industrialization, government support for manufacturing innovation, and expanding applications in countries like China, Japan, South Korea, and India. China, in particular, is investing heavily in local 3D printing capabilities as part of its broader push for technological self-sufficiency.

Latin America and the Middle East & Africa are emerging markets with growing interest in 3D printing for applications in healthcare, construction, and energy sectors, though adoption remains limited due to infrastructural and financial constraints. Overall, as regional governments continue to promote digital manufacturing through favorable policies and funding, the global 3D printing ecosystem is poised for continued expansion.

3D Printing Materials and Equipment Market Companies

- Hoganas AB

- SLM Solutions

- 3D Systems Inc

- Optomec

- Concept Laser GmbH

- LPW Technology, Ltd

- Stratasys Ltd

- Royal DSM N.V

- Arcam AB

- EnvisionTEC GmbH

- Arkema S.A

- Voxeljet AG

- Solidscape Inc

- EOS GmbH (Electro Optical Systems)

- ExOne

Segments Covered in the Report

By Material Type

- Ceramics

- Plastics

- Metals

- Others

By Product

- Polyjet

- Fuse Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- ColorJet

- Others (MJM, DLP, etc.)

By End-users

- Electronics & Consumer Products

- Automotive

- Medical

- Industrial

- Education

- Aerospace

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Also Read: 3D Printing Filament Market

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6204

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com|+1 804 441 9344